Environmental

Environmental Commitment

Kirby is committed to continuously improving the compatibility of our operations with the environment.

Management and the employees of Kirby pledge to:

Make safety, health, and the environment priorities in our business planning and risk management

Establish and maintain, in cooperation with public authorities and others, emergency preparedness procedures and plans to mitigate the effects of accidents which may occur

Conduct annual review and audit of Kirby’s Environmental Management System for continuous compliance

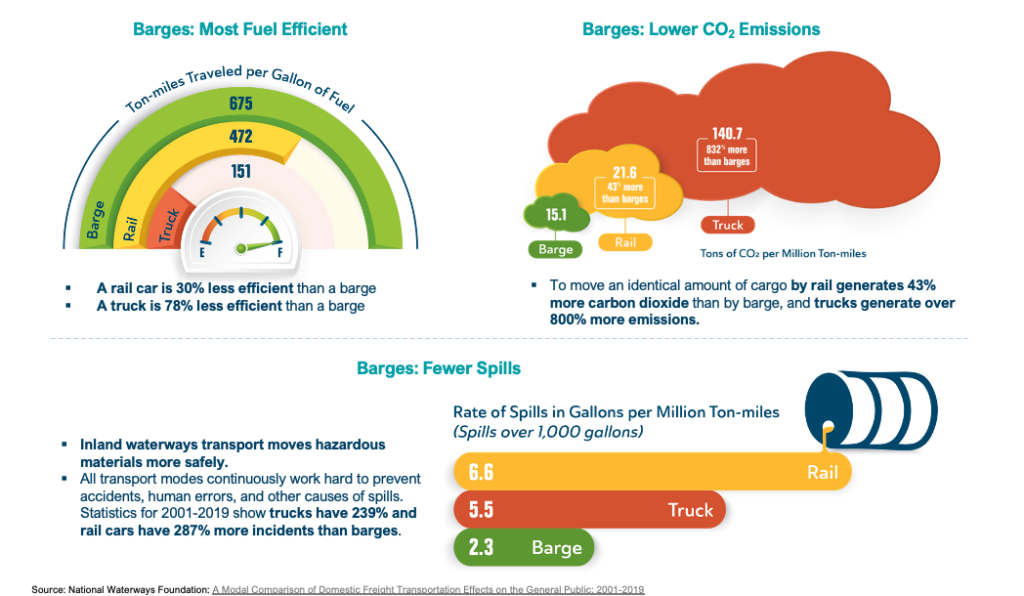

Marine Transportation: A Good News Story for Safety and the Environment

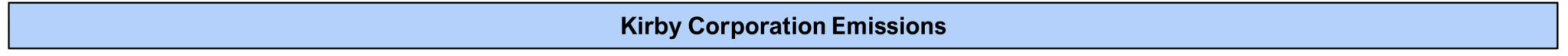

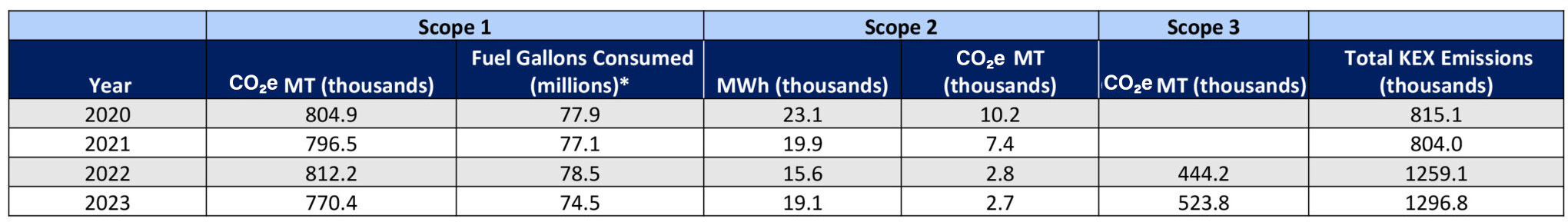

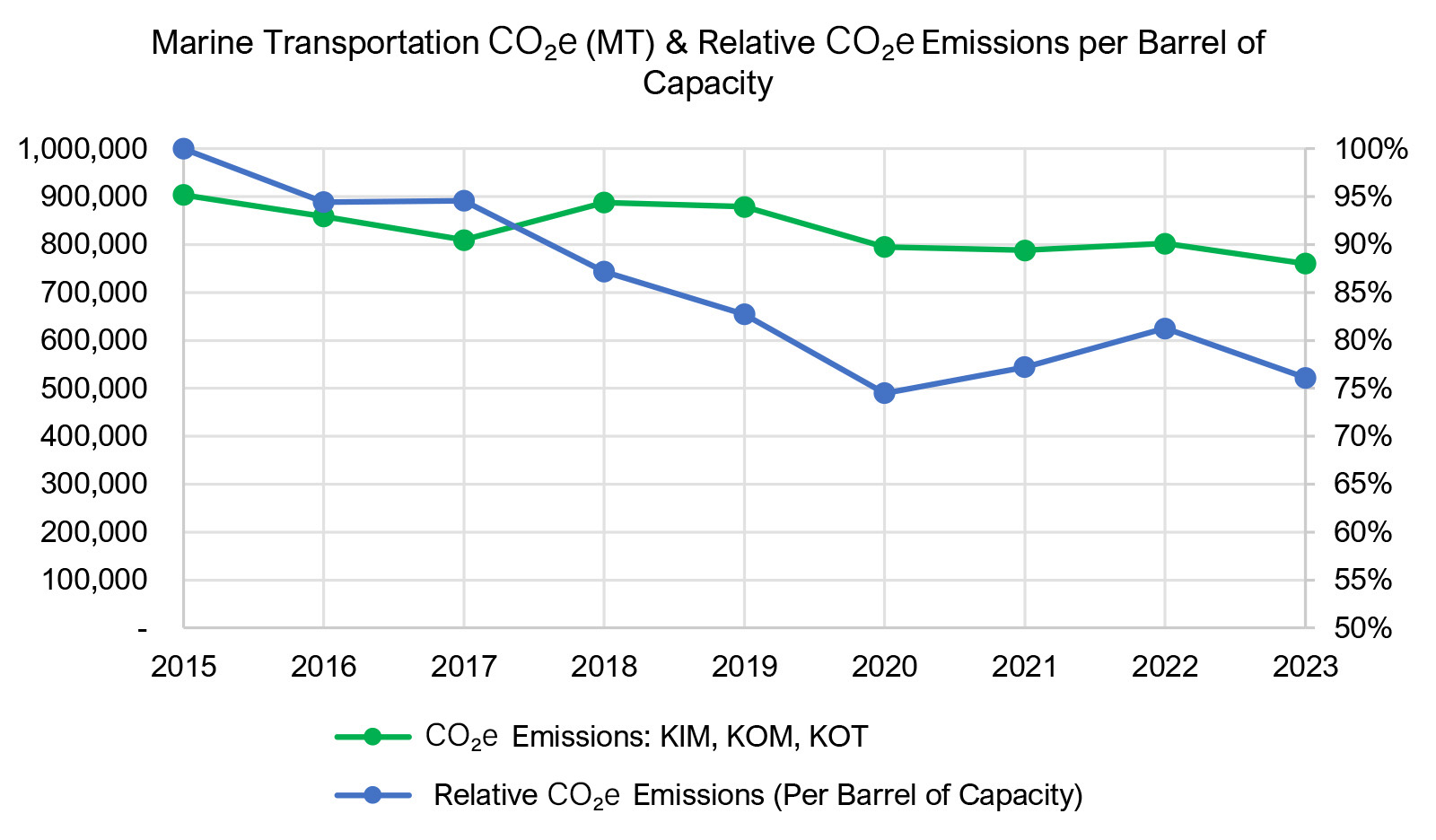

Marine Transportation – GHG Emissions*

~99% of Kirby’s emissions are from the marine transportation fleet

Emissions Performance (2015 to 2023)

- Since 2015, total CO2e emissions have declined 16% despite significant growth in the fleet

- Total barrel capacity up 11%

- Result of inland fleet acquisitions offset by offshore fleet retirements

- Diesel consumption declined 5% ’19Y/’20Y primarily due to reduced activity associated with the COVID-19 pandemic

- Since 2015, average age of inland boats is down ~13 years and offshore boats is down ~18 years

Emissions Reduction Targets

- Short term target: Overall, Kirby emissions declined 24% per barrel of capacity by 2024, nearing our goal of 25%

- Long term target: 40% reduction of emissions per barrel of capacity by 2040

*Kirby Corporation Emissions Basis Methodology

Kirby Corporation – GHG Emissions Summary

Scope 1 Emissions Performance

- ~99% of Kirby Corporation Scope 1 GHG emissions come from marine transportation operations, primarily towboats and tugboats

- Ultra-low-sulfur diesel fuel consumption and CO2e emissions have declined 16% since 2015 despite significant growth in the number of vessels in the fleet

- Emissions data reporting project completed in 2022 – helps Kirby to better understand its emissions footprint on a micro level and assist customers in achieving their emissions reductions goals

Scope 2 Emissions Performance

- While Scope 2 MWh increased year on year, overall CO2eMT declined due to providers utilizing more renewable energy sources for electricity, such as wind and solar

- 100% of Scope 2 energy is consumed from the grid

- Signed a 36-month agreement for 100% green e-certified energy in April 2020 for all Kirby marine transportation facilities in Texas

- ECO Solutions Champion issued ~3,000 renewable energy certificates in 2023; 100% renewable representation

- ~20% of Scope 2 energy is renewable

Decarbonizing Initiatives – 40% Reduction by 2040

When it comes to decarbonizing the company, Kirby is pursuing many paths in order to achieve best results.

- Continuing Kirby’s commitment to decarbonization with a 40% intensity reduction by 2040 of Scope 1 Emissions–roughly 160,000 metric tons of CO2.

- Proactive implementation of existing tools and technologies:

- Biofuels with emission reductions of 20–30% per towboat or tugboat*

- Hybrid power technologies with reductions up to 80% per towboat or tugboat

- Engine re-powers with reductions of 15–20%

- Dedicated development of future carbon reduction techniques, alternative fuels, and power sources and their respective supply chains.

- Thorough establishment of procedures and best practices to drive emission reducing operations.

- Fuel management procedure

- Extensive fleeting network and fleet boat capacity enables delivery of barge equipment to customer docks with smaller horsepower vessels

- Company policy to require shutdown of main engines during cargo transfer (when safe to do so as determined by the captain)

- Repowering of fleet to use cleaner, more efficient engines

- Through the appropriate combination of these initiatives, the potential exists to meet emission targets without the application of carbon offsets.

Inland Marine – Hybrid Electric Towboat: M/V Green Diamond

Kirby is one of the first inland marine transportation companies to own and operate a diesel-electric hybrid towboat in the United States.

- Began service in 2024

- Proprietary in-house design, development, and construction for a diesel-electric inland push boat incorporating an energy storage system (ESS) that significantly reduce emissions

- Reduced maintenance schedule and costs against conventional vessels

- Efficiency gains in multiple operating modes

- Fuel savings potential of up to 80%

SPECS:

- Hybrid drive with two generators (1130 kW)

- Battery pack : 1243 kWh

- Charge time at dock (480 VAC, 200A): 6 hours

Kirby Offshore Marine

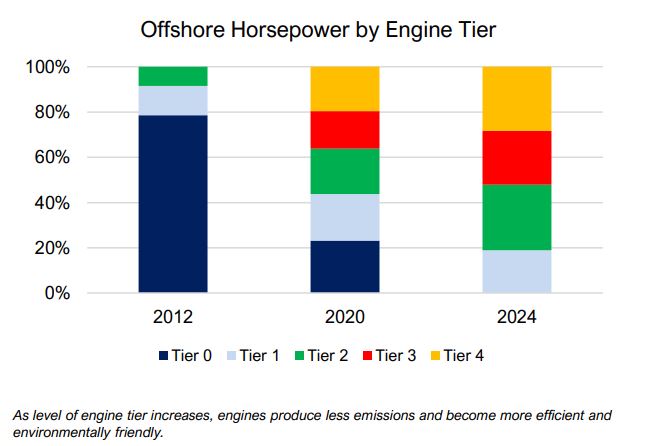

Kirby Offshore Marine was a first mover to integrate tier four engines into their tugboat fleet.

Going Above and Beyond – Marine Transportation

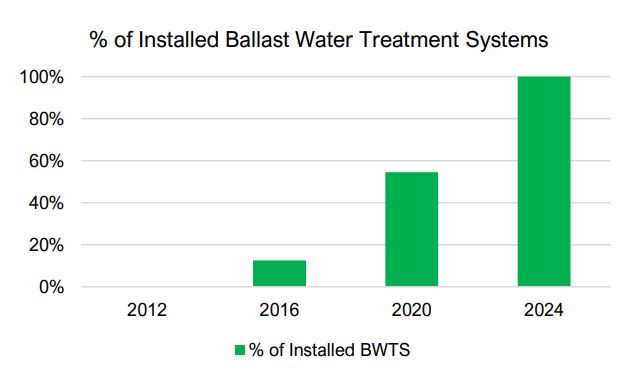

- Kirby implemented usage of ultra-low-sulfur diesel on all vessels in 2012

- All tank barges are double-hulled to better prevent environmental spills

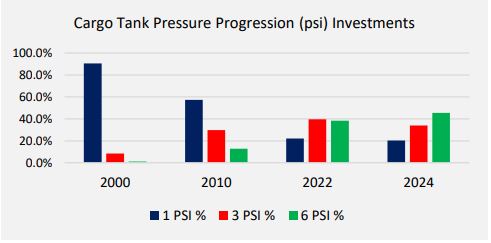

- Voluntary usage of 6 psi vs. 3 psi vapor relief value settings on inland tank barges (the industry standard) significantly reduce cargo vapor emissions*

- ~45% of Kirby’s fleet is fitted with 6 psi vapor relief values

- Kirby has the largest 6 psi barge fleet in the U.S.

- Company policy does not allow for the discharge of bilge overboard, even if the vessel is equipped with an oil-water separator

- Large tank barge fleet reduces unnecessary emissions and waste

- Dedicated product tows reduce barge cleaning between cargos

- Smaller fleeting boats reduce fuel consumption and emissions

- Linehaul service improves overall barge to boat ratio (Kirby 3:1, industry 2:1)

- Ongoing boat and engine replacement program improves efficiencies and reduces emissions

- Starting in 2014, Kirby began transitioning its engine service oil changes from mineral to synthetic to better serve the equipment and the environment. 70% of inland marine boats use synthetic oil

- Barge cleaning facility operations go beyond regulatory standards

- Residual cargo recovery mitigates waste, and efficiency of cleaning process reduces emissions by 98%

- Kirby serves as a leader in numerous industry organizations that help define industry regulations and improve air and water quality

* 6 psi barges are more environmentally friendly and have a lower probability of releasing vapors into the air than 1 psi and 3 psi barges.

Limiting Our Impact on the Environment

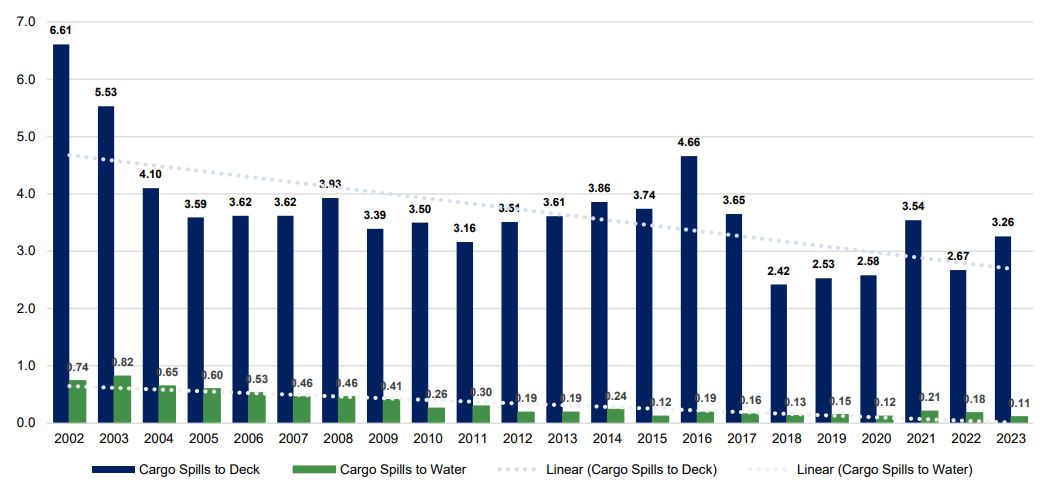

In 2022, Kirby transported 472.1 million barrels of cargo transported with only 12 gallons spilled to water.

- At Kirby, no spill is too small–all cargo spills, even if only 1 drop, are recorded and reported

- Cargo spills to water have declined since 2002, representing a 85% decrease

- Kirby is committed to continuous improvement through cargo transfer audits, regular tankerman proficiency evaluations, advanced training courses, review and implementation of best practices, review of near-miss events, and quarterly tankerman meetings

- In 2023, approximately 4,000 cargo transfer audits were completed

Inland vs. Offshore Marine

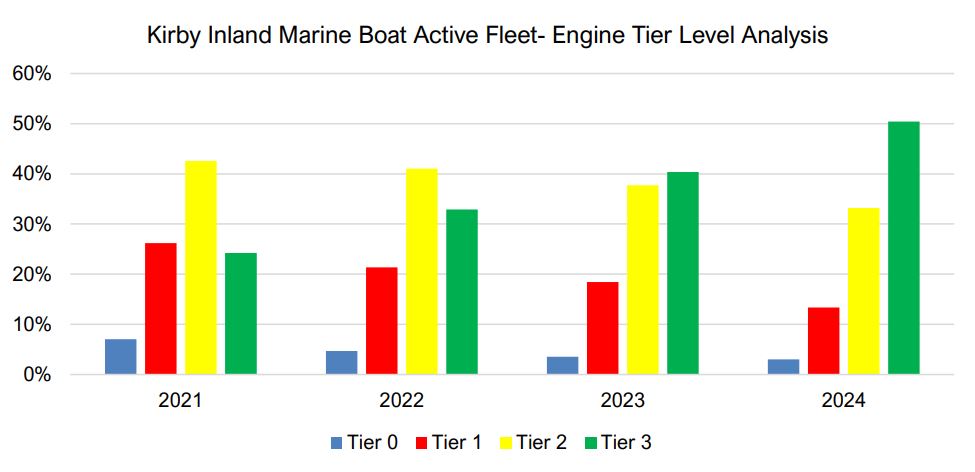

- By the end of 2024, Kirby will have spent over $29 million dollars over the last four years upgrading and repowering vessels from lower tiered engines to more environmentally friendly tiered engines

- In the last four years, Kirby’s Tier 3 equipment has increased by ~25%

As engine tier level increases, engines produce less emissions and become more efficient and environmentally friendly

As engine tier level increases, engines produce less emissions and become more efficient and environmentally friendly

Engine Tier Strategy

Since entering the offshore market Kirby’s investment strategy has removed all Tier 0 engines

Since 2015 Kirby’s investment strategy has spent

$200M+ on Tier 3 and 4 engines and boats

Kirby is committed to a cleaner and more efficient offshore fleet

Since 2017, Kirby Inland Marine has spent over $10 million dollars investing in solar panels for over 700 barges that power the high-level alarm systems

- Allows the barges to load and discharge at facilities that do not have high level alarm hook ups on shore

- Ensures tankerman can use the alarm system on loads and discharges which gives them a safety system to help prevent spills to the environment

Environmentally Friendly Oilfield Solutions

Electric Fracturing Units

E-frac units operate using natural gas turbines or highly efficient natural gas reciprocating engines together with electric motors, reducing their environmental footprint

E-frac units provide enhanced levels of automation, removing workers from potentially dangerous areas and reducing wellsite headcount

Compared to conventional fracturing units, e-frac units:

– Provide over 2.5x the output per trailer

– Reduce emissions, including NOX reduction of 72%

– Reduce average sound pressure by up to 69%

– Reduce road traffic associated with diesel transport

Dual Fuel and Quiet Fracturing Units

Environmentally Friendly Power Generation Solutions

Natural Gas Reciprocating Generators

High Mobility: 53′ x 8.5′ x 13.5′

Wide Operating Range: Up to 122°F operation

Mobile Power Distribution Systems

Enables highly scalable power plants and microgrids

Multiple local generator inputs

Utility infeed connection and synchronization

Energy storage system connection

Proprietary power control and management system enables synchronization and remote control of all local inputs (ESS and generators)

Self-contained: Drive-up and plug-in (no additional rig-up)

Highly scalable: Platform-based design (allows for smaller systems or use of multiple systems to meet different power demands)

Going Above and Beyond – Distribution and Services

- Largest manufacturer of frac units with Tier 4 engines, achieving higher EPA standards

- Development of dry gel hydration units eliminates usage of mineral oil and/or diesel in slurries pumped into wells

- Paint and solvent re-use and recycling reduces waste by-products by 95% and recovers 99% of solvents for re-use

- LED lighting installed in key facilities to reduce energy consumption

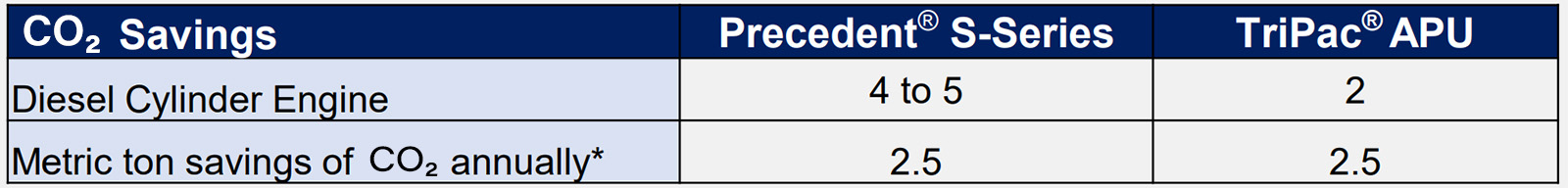

- Thermo King sells environmentally friendly products including:

ThermoLite® solar panels deliver clean, reliable performance in a wide variety of applications, resulting in

longer battery life, decreased waste, lower fuel consumption, and reduced emissions

Precedent® S-Series refrigeration units achieve Evergreen CARB and EPA emissions compliance while

adding performance

TriPac® Auxillary Power Units (APUs) meet Tier 4 EPA regulations and drive unit efficiency and productivity